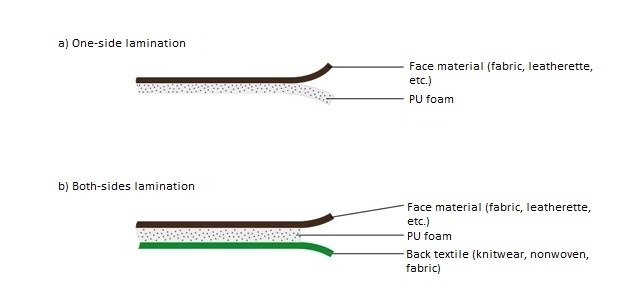

Production of layered materials in a metre, which includes a layer of PU foam. The PU foam is flame-moulded and then bonded to another substrate between the rollers of the line. The foam melt acts as an adhesive. The passage through the line allows simultaneous double-sided lay-up.

Output is layered material with PU foam layer thickness up to 40 mm, maximum working width of the machine 2 000 mm.

Brand new investment - available from Q2 2025

Standard machine for continuous operation with linear gas burner

Additional trays for fabric, foam, backing material and finished products to compensate for downtime during material changeovers

Specialised accumulators and distributors to increase production capacity